TRACING TECHNOLOGIES processes allow industry to protect their brands, products and market shares by using inert and invisible markers to human eyes with dedicated detection systems.

The process also brings to industry new sorting capabilities for post-consumer plastic packaging. A “Tracer Based System”

Tracer Based System

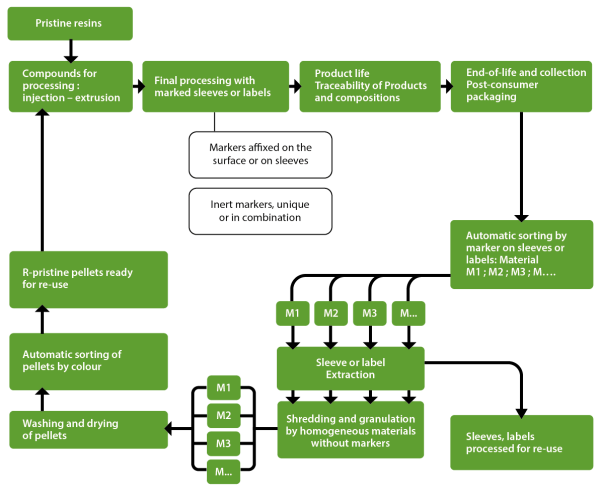

Flow chart on TBS

| Patents Families | Technical scope | Geography |

|---|---|---|

| Family 1 & 2 | Methods for authentication by chemical marking or tracing of an object or a substance |  France / United Kingdom / USA / Germany / China France / United Kingdom / USA / Germany / China |

| Advanced Method for securely authenticating an object or a substance by chemical marking or tracing. |  France / United Kingdom / China / Germany France / United Kingdom / China / Germany | |

| Family 3 | Application method for recycling materials from used objects. |  France / United Kingdom / China / USA / European Union France / United Kingdom / China / USA / European Union |

| Family 4 | Advanced processes for automatic identification of an object or material. |  France / USA France / USA |

ECODESIGN OF PRODUCTS for traceability and reuse at end of life.

Breakthrough processes to identify and sort automatically post-consumers packaging on the industrial recycling sorting lines.

This solution aims to comply with REACH, RoHS and WASTES framework Directives and standards.

Process results in a drastic decrease of the “environmental footprints (CO2), by the re-use of homogeneous R-products.

CO2 imprint of recycled materials is 1/10 of pristine materials.

Successful marking at very low concentration, only a few parts per million, by selected markers.

Tracing Technologies is proposing a unique, tamper-proof, life-long marking identifiable on industrial sorting machine, including in the mass of dark or black materials. The success of the TRIPTIC project realized in 2009-2014 with polymers used in the car manufacturing industries was successfully validated by academic laboratories and major automotive industries involved.

Some very positive achievements :

- Successful trials of marking at 30 ppm concentration of markers in black polymers (particle size on samples of 3 cm2) with instant detection on industrial sorting line at 3 m/s. 100% success detection rate.

- 100% successful detection rate after a weathering equivalent to 15 years. (Normative weathering tests)

- Validation of the C02 imprint gain obtained by using recycled material versus pristin resins (1/10).

- Long-life validation of traceability of a product or material. Positive confirmation and compliance to REACH, RohS and Wastes Directives.

Markers incorporation without disruption of the manufacturing process: Compounds and master-batches are proposed ready for use.

Very low concentration of markers provides a very consistent and economical process.

Wide reading devices are proposed given the markers type used: UV, IR, NIR …)

Readers set on industrial sorting lines will enable to stock homogeneous and reusable recycled materials.

A dedicated reader will allow to certify each quality of any stock

Overall traceability of each material used in the supply chain at discretion of the industry; from eco-design to end of life.